SUPPORTING AND SECONDARY INJECTION MOLDING

EQUIPMENT INCLUDES:

Mold Temperature Controllers, Portable Chillers, Thermolators, Dryer Ovens, Hopper Dryers, Automatic hopper Feeders, Automatic Color Feeders, Conveyors, Punch Presses, Pad Printing Hot Stamping, Ultrasonic Welding, Assembly Area, and a Complete Tool Room Facilities, Automated Central Material Handling System, Robotic Part Removal Systems.

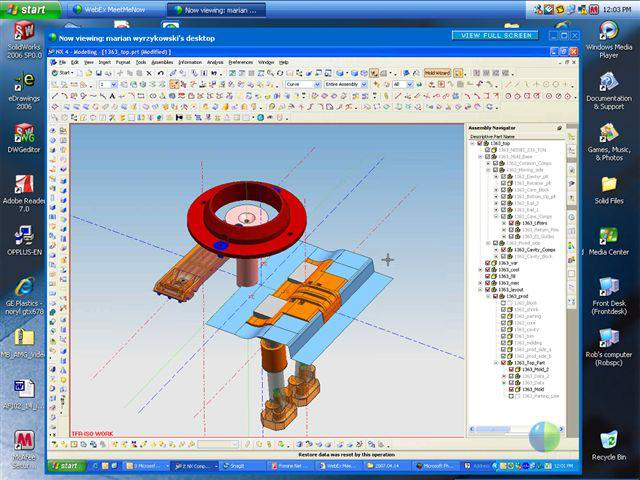

Tooling:

Echo Molding was started as a tool shop back in 1975. Partnered with a wide range of tooling options we offer in house low cost quick delivery aluminum tooling to high precision hardened tool steel molds. We also offer oversea’s molds to suit your projects needs which gives us a large range of tooling options.

Tool room equipment:

CNC Milling Centers up to 60” X 80”

CNC turning centers up to 24” Diameters

4+5 Axis CNC Milling centers

EDM and Wire equipment

Grinding, Drilling, Milling and all necessary support equipment.

Assembly and Packaging:

Full service assembly and packaging solutions.

Assembly:

Decoration: Hot stamp, pad print, silkscreening and label transfer.

Sonic Welding, heat staking, Inserting, glueing

Packaging of finished product. Kitting

Heat Bending, Heat Sealing.